We had been requested to develope automation system for a gas station lighting control. It involved development of functionality of lighting equipment switching on/off both by command and by timer. Furthermore, the remote control through a tablet or a computer was required.

In order to elaborate engineering implementation, control configuration is developed.

1. User controls lighting elements through an application program;

2. Tablet transmits data (via Wi-Fi, protected network) to the routing block;

3. Routing block receives signal and transmits it to the control block, which in turn switches lighting equipment on or off;

Settings (switching on/off by timer, switching lighting off by the daylight) is set through the program interface

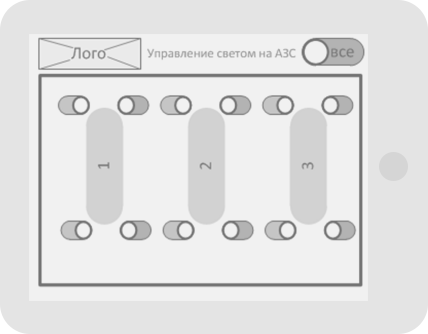

We develop an application prototype. Interface must be user-friendly (lighting should be controlled by the gas station operators or refuellers.)

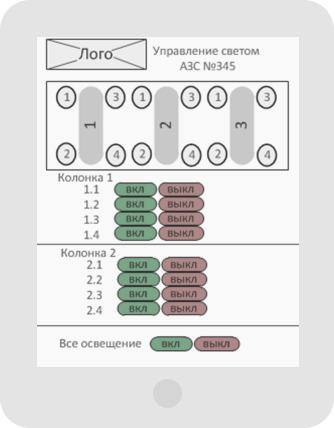

Trying to arrange gas columns at the gas station. Lighting equipment is switched on/off by the separate buttons. We apply industrial principle as that in the car keyfob: one function by one button.

We reject this principle because of non-informativity and interface overload. We develop a more advanced solution.

Direct linking of application to the existing ACS elements (controller and routing block) is impossible. For this purpose, we develop API to link the controller, routing block and application into the single system. We get into the controller documentation and program it.

We program the application according to the developed interface design. We test application communication with the entire system. If communication is not established, an error message is displayed to the user.

It is carried out by professional electrical technician. We prepare a wiring diagram. We assembly a lighting control cabinet and a routing block jointly with the electrical technician. See the lighting control electric circuit diagram and the assembled lighting control cabinet below.

We mount lighting equipment to the test bench and test it prior to handing over to the customer.

Click video below to see result.

Used equipment:

Lighting control module Uniel UCH-M111RX/0808, power supply unit Uniel UET-SPD-012A20 Module, master controller, radio interface and state-of-the-art enclosures for equipment environmental protection (IP 65). All the automation system elements are mounted on a DIN rail inside the cabinet.

Lighting remote control system for gas station must comply with the fire and electrical safety requirements; enclosure rating must comply with the IP requirements. We select each component based on these requirements.

Для того, чтобы мы смогли Вам предоставить доступ расскажите немного о себе

Access to the repository (the source code platform Task On 2) is sent on request.